- Promoting energy savings

- Protecting the long term health of the building substructure

- Promoting a healthy environment inside a building.

- Thermal Insulation

- Acoustic benefits (rain screen facades make for a more quiet building interior).

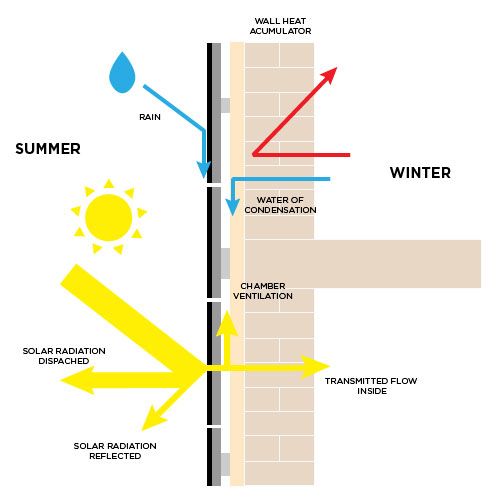

What is a ventilated facade?

Also Known as Rain Screens are the most technologically advanced and effective method of façade design yet devised for controlling water penetration into a building.

Added benefits are:

Types of Ventilated Façade’s

Drained and Back Ventilated

Far and away the more commonly used of the two. Provides all of the above benefits at a much more affordable price.

The interior wall or “Inner Leaf” is sheathed, flashed, and covered with an air vapor barrier.

Air is allowed into the cavity behind the “Outer Leaf” to provide some pressure equalization keeping much of the rain water out of the cavity. Some small amount of rain water is expected to get behind the cavity and this moisture is both drained from the system and also dried by the flow of air in the cavity.

Pressure Equalized

The Rolls Royce of the Ventilated Façade, pressure equalized systems use compartmentalization of the façade modules and baffles to the outside of the system to adjust to changes in exterior wind pressure, and truly equalize the air pressure inside and outside the system.

The added cost for pressure equalized system when compared to the added benefit, make them a more rare specification.

Thin Stone’s System is Patented

Ventilated Façade Materials

- 1/2″ thick natural stone. Mechanically fastened into the back of the stone itself (not the stone attachment system)

- Any stone that is quarried can be done with our rain screen system. Marble, granite, limestone, wtc.

- 12mm porcelain and sintered stones such as Cosentino’s Dekton also directly back anchored.

- On the interior of Newark Airport’s Terminal B, we used a Bendheim Frosted Glass without the back anchor.

Caulked Applications

Thin Stone’s system can be used in non-rain screen environment where a traditional caulked barrier wall is desired. There are still occasions in retro fit environments when it is not practical to modify the inner leaf and when it is still necessary to keep water out with sealants in the joints of the façade.

- Our system can be used in this way without modification.

If it is the light weight nature of our system that is desired, then a perhaps the rain screen or barrier wall question is secondary. In this case, either can be used.

Over-Cladding

- Because of the light-weight nature of our product, there are times when it is advantageous to leave the existing façade in place and simply apply our product directly over the existing façade.

- Thin Stone can help to guide the process of engineering and determining the sufficiency of the old substrate in carrying the new one.

- It is often possible to install a new façade with much less disturbance to existing tenants.

Interior Open Joint

Thin Stone’s system has been designed for interior open joint applications in order to provide a new modern look to the interior wall cladding. We have used the system on interiors to clad:

- Perimeter and Elevator Lobby walls

- Interior columns

- Ceilings and soffits

Our system can be knife mitered to provide a thick cubic look to exposed edges. A 2″ thick miter is our most used thickness, but miters up to 9″ thick have been provided.