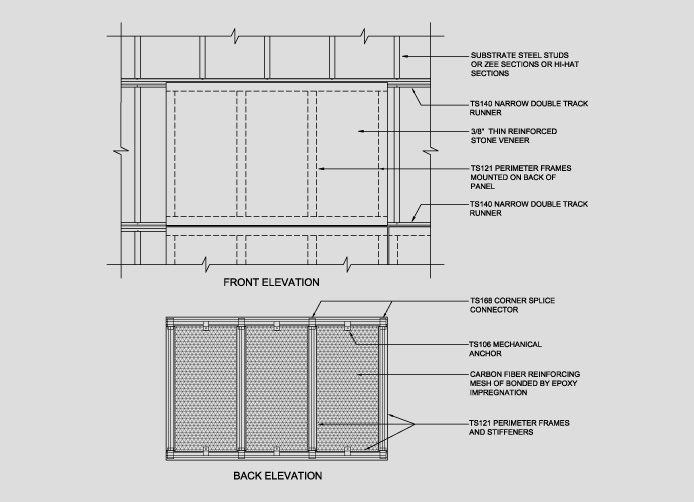

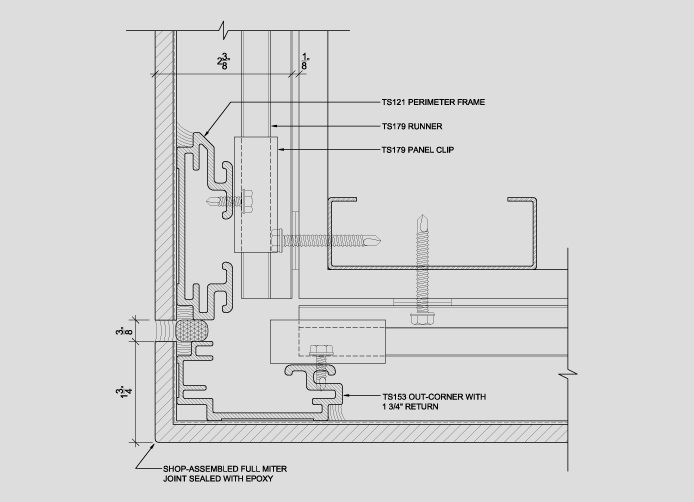

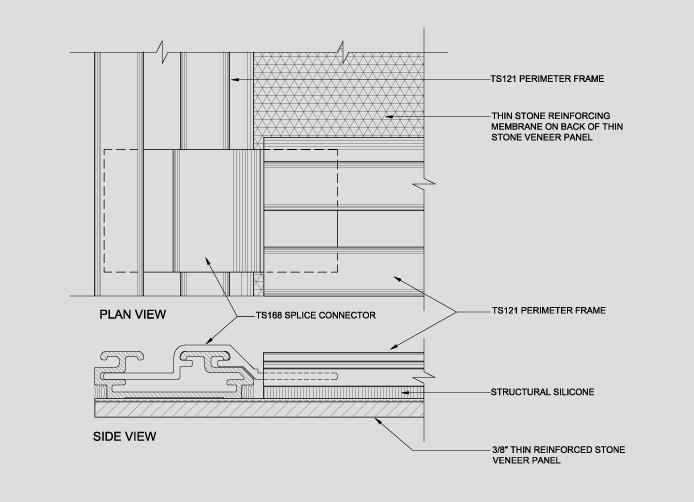

Typical Wall Panel

Details illustrate construction of a typical wall panel with TS121 Perimeter Frames and TS121 Intermediate Stiffeners are interlocked at their intersections by TS168 Corner Splice Connector designed to allow slip movement. The Wall Panel rides in the continuous sockets of the TS140 Narrow Double Track Runner. This allows some compensation for possible movement due to temperature differentials, seismic forces, or building sway due to high windloads.

Call Us at (973) 882-7377 For DWG or PDF Files

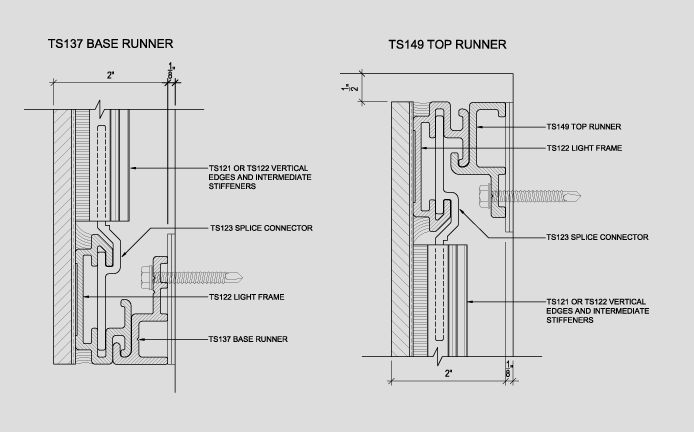

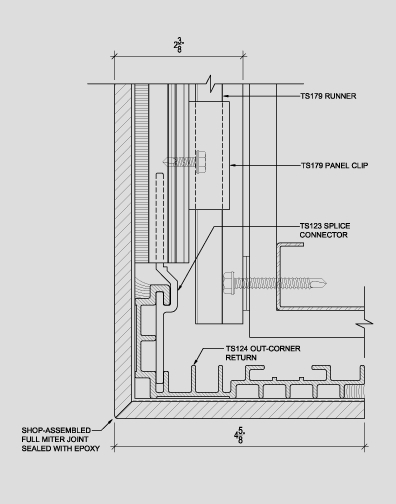

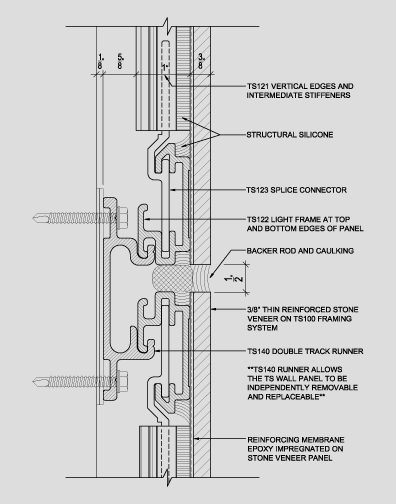

TS122 Light Frame

The TS122 Light Frame is used at the top and bottom panel frames when the double track runners are used. See Detail 07. The verticals and intermediate stiffener, if necessary, are usually TS121 Perimeter Frame.

Call Us at (973) 882-7377 For DWG or PDF Files

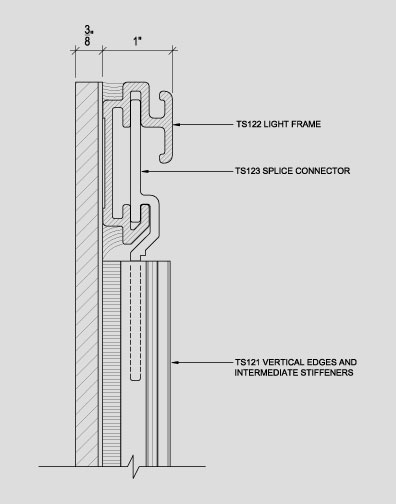

TS106 Mechanical Anchor

Some building codes require a mechanical connection between the stone veneer panel and the building structure. The TS106 Mechanical Anchor makes a bridge connection between the TS121 Perimeter Frame and a self-locking wedge type of expansion anchor which is shop-inserted into a prepared hole in the back of the fascia panel. When properly installed, this self-locking anchor insert produces a substantial pull-out value which varies with the physical characteristics of the particular type of stone involved.

Call Us at (973) 882-7377 For DWG or PDF Files

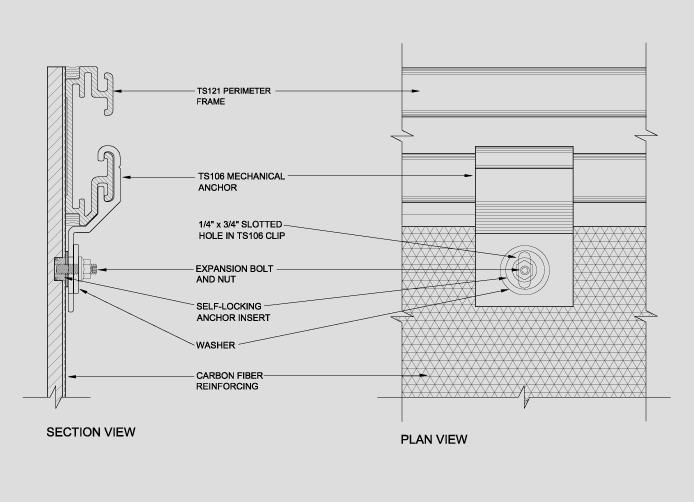

TS168 Corner Splice Connector

The TS168 Corner Splice Connector makes a structural slip connection at corners between two (2) intersecting frames. The slip-connector allows some movement in both directions to compensate for possible movement in the panel due to temperature differentials, seismic forces, or high windloads.

Call Us at (973) 882-7377 For DWG or PDF Files

TS140 Narrow Double Track Runner

The TS140 Double Track Runner is used to support the top and bottom of adjacent panels. The panels have the TS122 frame at the top and bottom of each panel. The verticals are usually TS121. This is economical since it requires only one piece of track for each panel. It is shaped to automatically create 1/2″ joint. If a 3/8″ joint is required, the extrusion will be set back 1/16″ from each panel edge thus closing the gap by 1/8″ creating a 3/8″ joint.

Call Us at (973) 882-7377 For DWG or PDF Files

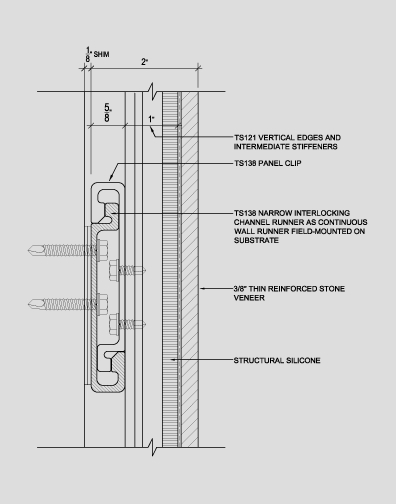

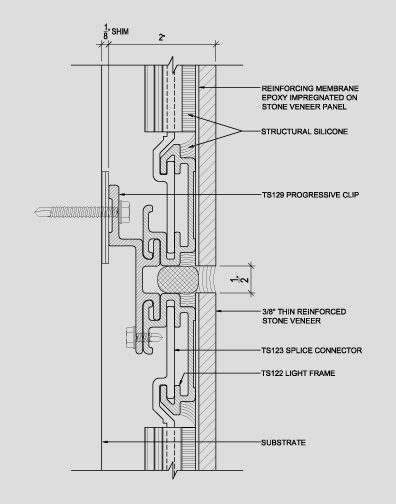

TS129 Progressive Clip with 1/2″ Joint

The TS129 Progressive Clip is pre-attached to the top frame of a panel and provides the means of a screw attachment to the substrate. It also provides a socket to receive and carry the next panel above and automatically fixes the joint width of 1/2″. If a 3/8″ joint is required, the extrusion is set back 1/16″ from the top and bottom panel edges which closes the gap between panels to 3/8″. This allows the installer to work progressively upward instead of installing all the horizontal runners than the panels. The TS129 is compatible with TS138 and TS140.

Call Us at (973) 882-7377 For DWG or PDF Files

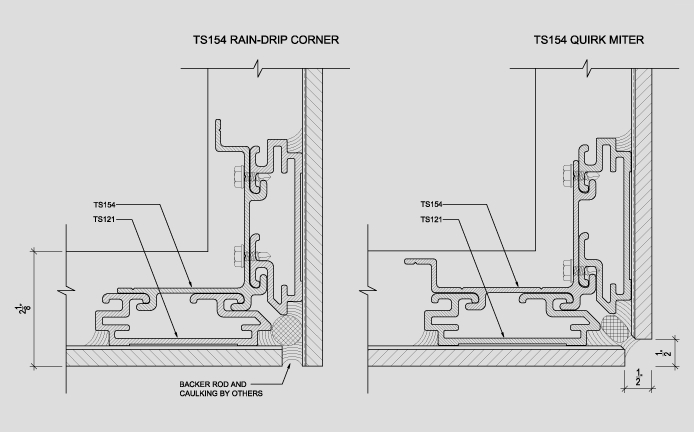

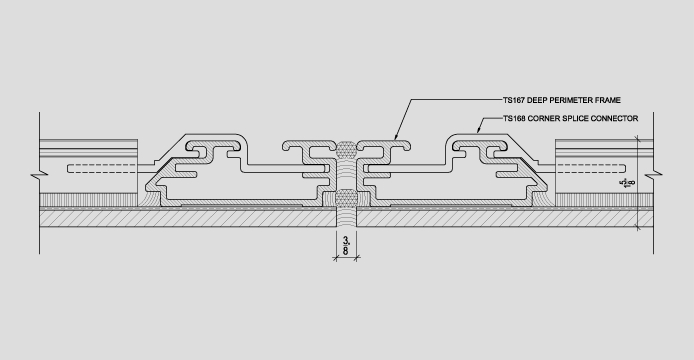

TS167 Deep Perimeter Frame

The deeper frame allows the joints to be double caulked and is particularly useful in high-rise projects where water penetration is critical. The deeper frame is also stronger and allows greater spans to be engineered.

Call Us at (973) 882-7377 For DWG or PDF Files

Contact Us for DWG or PDF Files

"*" indicates required fields